Shedding Light on Industrial Warehouse Lighting

Industrial warehouse lighting stands as a fundamental aspect of operational efficiency and workplace safety. Within the vast expanse of a warehouse, proper illumination becomes more than a convenience—it's a necessity for optimizing productivity, ensuring safety, and supporting seamless operations.

The Significance of Proper Lighting in Industrial Warehouses

Safety Amplification

In the dynamic environment of an industrial warehouse, safety takes precedence. Adequate lighting is paramount in preventing accidents, reducing hazards, and ensuring the overall well-being of the workforce. Well-lit pathways, clearly illuminated machinery, and bright workstations significantly contribute to accident prevention and employee safety.

Productivity Enhancement

Lighting directly influences productivity levels. Properly lit environments reduce eye strain, fatigue, and errors, fostering a conducive atmosphere for employees to work efficiently. Clear visibility and well-illuminated areas facilitate faster and more accurate inventory management and order fulfillment.

Energy Efficiency

Modern advancements in lighting technology have paved the way for energy-efficient solutions. LED lighting, in particular, stands out for its lower energy consumption compared to conventional options, resulting in reduced operational costs and a smaller carbon footprint.

Types of Lighting Solutions

LED Lighting

LEDs have emerged as the go-to choice for industrial warehouse lighting. Offering superior energy efficiency, durability, and reduced maintenance needs, LED fixtures provide bright, uniform lighting that suits the expansive nature of warehouses. Customizable options allow tailored solutions to fit specific warehouse layouts and lighting requirements.

High-Intensity Discharge (HID) Lighting

HID lighting, including metal halide and high-pressure sodium lamps, has traditionally been used in industrial settings. While these lamps offer high brightness, they are less energy-efficient and have longer warm-up times compared to LEDs. However, they're still employed in some warehouses due to their initial cost advantage.

Fluorescent Lighting

Fluorescent lights are a cost-effective option but have lower energy efficiency and a shorter lifespan than LEDs. Despite this, they still provide adequate illumination for some warehouse spaces.

Factors to Consider When Choosing Lighting for Warehouses

Light Distribution and Uniformity

Uniform lighting distribution is crucial to reduce shadows and ensure consistent illumination across the warehouse floor, enhancing safety and operational efficiency.

Color Rendering Index (CRI)

A high CRI is essential in warehouses where color accuracy matters for tasks such as sorting and quality control.

Motion Sensors and Smart Controls

Integrating motion sensors and smart controls can optimize energy usage by adjusting lighting levels based on occupancy or natural light conditions, offering both energy savings and prolonged fixture lifespan.

Maintenance and Longevity

Selecting lighting fixtures with longer lifespans and minimal maintenance needs reduces downtime and replacement costs in the long term.

Cocoweb Ultra Bright Warehouse Lights: An Exceptional Lighting Solution

Among the myriad options available, Cocoweb Ultra Bright Warehouse Lights stand out as an exceptional choice for industrial warehouse illumination. These lights combine the latest LED technology with durability, providing unmatched brightness and efficiency. With customizable options to suit varying warehouse sizes and layouts, Cocoweb Ultra Bright Warehouse Lights offer:

- Unparalleled Brightness: These lights deliver powerful illumination, ensuring optimal visibility throughout the warehouse space.

- Energy Efficiency: Built with energy-saving LED technology, they minimize electricity consumption while maintaining superior brightness.

- Longevity and Durability: Designed to last, these lights boast a prolonged lifespan, reducing maintenance hassles and costs.

Conclusion: Embracing Innovative Solutions for Enhanced Warehouse Lighting

In conclusion, the choice of lighting solutions profoundly impacts the functionality and safety of industrial warehouses. As highlighted, factors such as safety, productivity, energy efficiency, and maintenance play crucial roles in determining the most suitable lighting option.

Amidst these considerations, Cocoweb Ultra Bright Warehouse Lights emerge as an exemplary solution. Their cutting-edge technology, unmatched brightness, and adaptability make them a standout choice for warehouse illumination needs. By investing in innovative solutions like Cocoweb lights, warehouses can create well-lit environments that not only boost operational efficiency but also prioritize the safety and comfort of their workforce, setting the stage for continued success in the industrial landscape.

Recent Posts

-

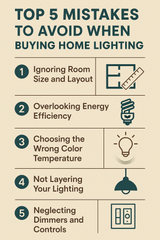

Top 5 Mistakes to Avoid When Buying Home Lighting

Lighting plays a crucial role in shaping the ambiance, functionality, and aesthetic appeal of your h …26th Jun 2025 -

Why Lighting Is the Most Underrated Design Element in a Room

Walk into a well-designed space, and you might first notice the color of the walls, the statement fu …13th May 2025 -

How to Choose the Perfect Painting for Your Home or Office

When it comes to decorating your space, choosing the perfect painting can be a game-changer. A well- …7th Feb 2025